Introduction of Hebei province light alloy wheel engineering technology research center

Hebei province light alloy wheel engineering technology research center( hereinafter referred to as engineering center) supported by Qinhuangdao Dicastal XingLong Wheels Co.,Ltd, cooperates with Qinhuangdao Yanshan University Modern Integrated Manufacturing Technology Development Co., Ltd. In May, 2012, Engineering center passed acceptance of Hebei Science and Technology Office, Hebei Finance Department , Hebei Development and Reform Commission, officially included in the provincial engineering technology research center management sequence.

According to industry trends, technology needs and key technical issues, combined with their own advantages, engineering centers identified four research directions:(1) The new energy-saving and lightweight wheel technology research; (2) The new manufacturing equipment and complete set of technology research; (3) Large wheel manufacturing technology research; (4) Wheels integration development technology research.

The engineering center has more than 30 staffs, of which more than 70% have middle or senior professional titles. Through product research and technology innovation, engineering center has trained a complete-majored, rational allocated high-quality and innovative technological team. The engineering center has 4,000 square meters of space for engineering test, 700 square meters office space, nearly 30(sets of) equipment and machine which are worth more than 25 million Yuan. The engineering center conducts engineering and technology tests aiming at new technology and new processes of wheel products; able to carry on plenty of tests and inspections of wheel products; moreover, has the capabilities of researching and development wheel manufacture key equipment and complete sets of technology.

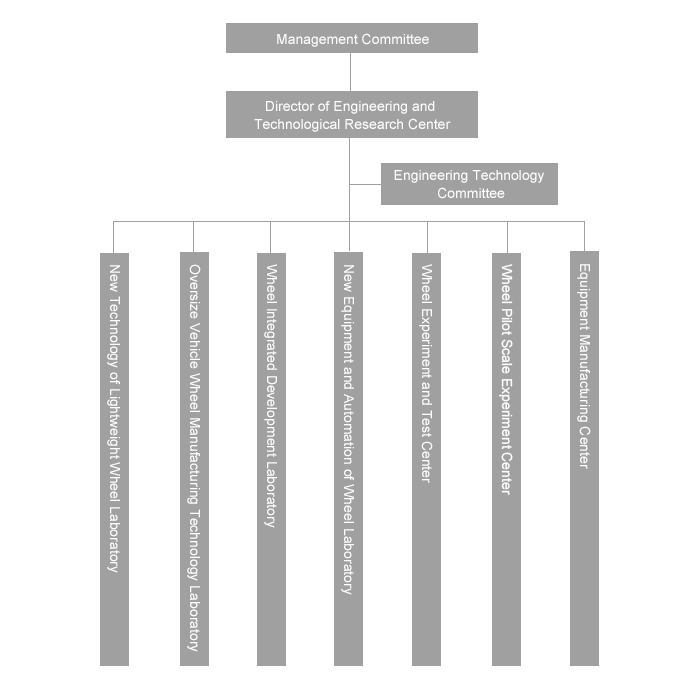

The engineering center has established an effective operational mechanism and a sound management system, setting up management committee and project technical committee. The director is thoroughly responsible for his department in the operation of engineering center which relies on the leadership of The Group and cooperative company, management committee is responsible for the overall operation and decision-making on major issues of the engineering center, project technical committee is responsible for the technological field, the director of the engineering center conducts a comprehensive management.

The engineering center actively carries out technical exchanges, promotes industry-university-research cooperation, fully mobilizes and uses industry human resources, technical resources and industrial resources, tackles the industry key common technical problems combining scientific research institutions and the enterprises in the same industry, jointly cultivates high-tech talents,conducts strategic research and development together, promotes technological upgrading within the industry,and provides technical advice and technical services to enterprises in the industry.

Under the strong support and leadership of Hebei Science and Technology Office,Qinhuangdao Science and Technology Bureau,Technology Bureau of Development Zone, guided by the market demands, taking the wheel products as objects and lightweight as target,the engineering center will develop into a domestically first-class light-alloy wheels engineering technology research center that features new products, new technology,new processes,new equipment and complete sets of technology.

Organization Chart of Hebei Province Light Alloy Wheel Engineering and Technological Research Center

Introduction of The Technology Center of The Industry Group

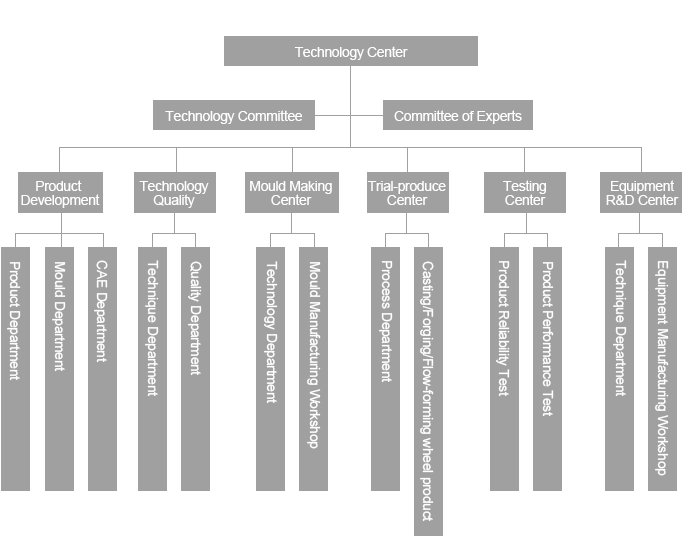

The Technology Center of Sinolion Industry Group is the R&D center of new product, new technique. There are professional CAD/CAM/CAE software which can provide 2D and 3D design and programming of products and molds according to the requirements of the clients, do performance analyses with finite-element analyses technology to make sure the properties meet design requirements, simulate forging and casting process to ensure the rationality of forging and casting technology. The technique center is fully equipped with test and inspection equipment and qualified for inspection and test in four fields of wheel size, metallurgical performance, reliability and safety and coating performance.

In recent years, the technology center undertakes more than ten technological projects of national or provincial level, accomplishes tens of independent technical projects and applies for more than ten patents every year. We carry out extensive scientific and technological cooperation with universities like Yanshan University, scientific research institutions and professionals doing researches in different gradations of corresponding domains. We have obtained many achievement, among them, the project of “aluminum alloy casting wheel critical equipment and complete set of wire technology” win the second award of scientific and technological progress of Hebei province.

The Technology Center was identified as Enterprise Technology Center of Provincial Level by Hebei Development and Reform Commission, Hebei Science and Technology Office, Hebei Commerce and Industry Office and Finance Department in October,2011.

Organization Chart of Technology Center of Sinolion Industry Group

Module One: Product Research and Development

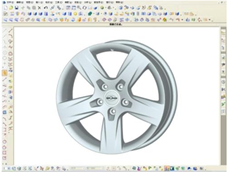

The technology center has a strong R&D team and research capacity, the research staffs have rich experience of product design and are proficient in CAD/CAM/CA software. They are able to complete the wheel development when clients only provide the necessary data of assembling dimensions, loading, weight requirement, etc. They can also exchange the data with clients directly and have the synchronous development capacity.

|

2D design : |

|

3D design: |

|

Module Two: Module Research and Development

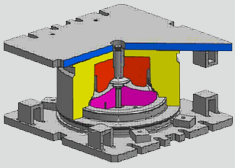

Technology center has strong ability of mould design and manufacturing. It can independently accomplish the design of casting mould, forging mould, and flow forming mould on the basis of different technological requirements of wheels and simulate the processing technique with the advanced CAD/CAM design technique.

|

Forging mould: |

|

Flow forming mould: |

|

|

Casting mould: |

|

Mould processing simulation: |

|

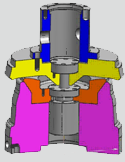

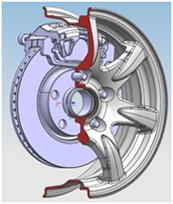

Module Three: Assembly Simulation

Technology center insures that the assembling ability satisfies the clients through the assembly simulation of wheel and axel, brake caliper, counterbalance, trim, etc.

Wheel assembly simulation:

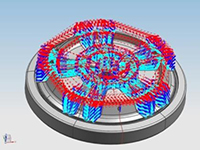

Module Four: Reliability Simulation

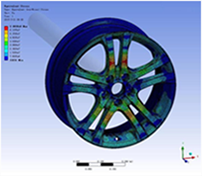

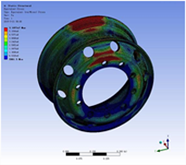

Technology center are able to make reliability analysis for wheels through finite-element analysis techniques to insure that the wheels can satisfy design requirements.

|

Impact test simulation: |

|

Bending test simulation: |

|

|

Radial test simulation: |

|

|

|

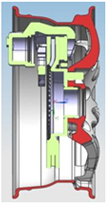

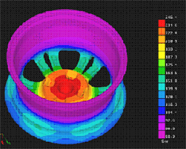

Module Five: Technology simulation

Technology center insures the rationality of wheel casting and forging technology by simulating the process of production.

|

Casting technology simulation: |

|

|

Forging technology simulation: |

|